AEROTIM Hangar

Location: Classified

Year of completion: Classified

Hangar Area: 400 sq.m

Crew Station: Area 94sq.m

Interior and concept development: Dan Vakhrameyev

–––––––––––

Impossible to describe AEROTIM in one sentence.

It is a team of unique athletes and creatives led by Timur Fatkullin. This collective is exceptionally skilled in aerobatics, freestyle motocross, and skydiving. Their true spirit of exploration has brought numerous awards and achievements, including Champions of the $1 Million GoPro Challenge (2020 and 2023), GoPro Awards recipients, and World Intermediate Aerobatics Champions (2019).

Versatile in his projects, Timur Fatkullin navigates an intense schedule between launching a men’s jewellery collaboration with designer Valeriia GUZEMA and producing AEROTIM’s first full-length film “Full Force”, telling the story of Ukrainian Army Aviation.

When Timur reached out with the idea of developing a hangar — a proper maintenance space for all SPORT aircraft and a meeting point for his crew — we accepted without hesitation. For a number of reasons, it proved to be one of the most interesting and demanding construction projects we have ever executed.

–––––––––––

“The overall design language remains deliberately restrained, relying on exposed surfaces, honest materials, and precise detailing to create a mature, disciplined environment suited to pre- and post-flight routines,” - Dan Vakhrameyev's comments.

photographer Andriy Bezuglov

The primary entrance is formed by a full-width gate covered with raw zinc sheets. This vertically lifting system enables unobstructed aircraft movement and establishes a direct visual connection between the exterior and interior. During daylight hours, natural light enters through the polycarbonate upper fronton section, reinforcing the façade’s functional and aviation-driven character.

The project is a multifunctional aircraft hangar that combines repair and maintenance areas, storage, and second-floor crew facilities within a single volume. The primary space is organized around a full-height hangar hall designed to accommodate light aircraft. The structure is fully exposed, including steel trusses, corrugated metal roofing, and visible technical air-duct and engineering systems.

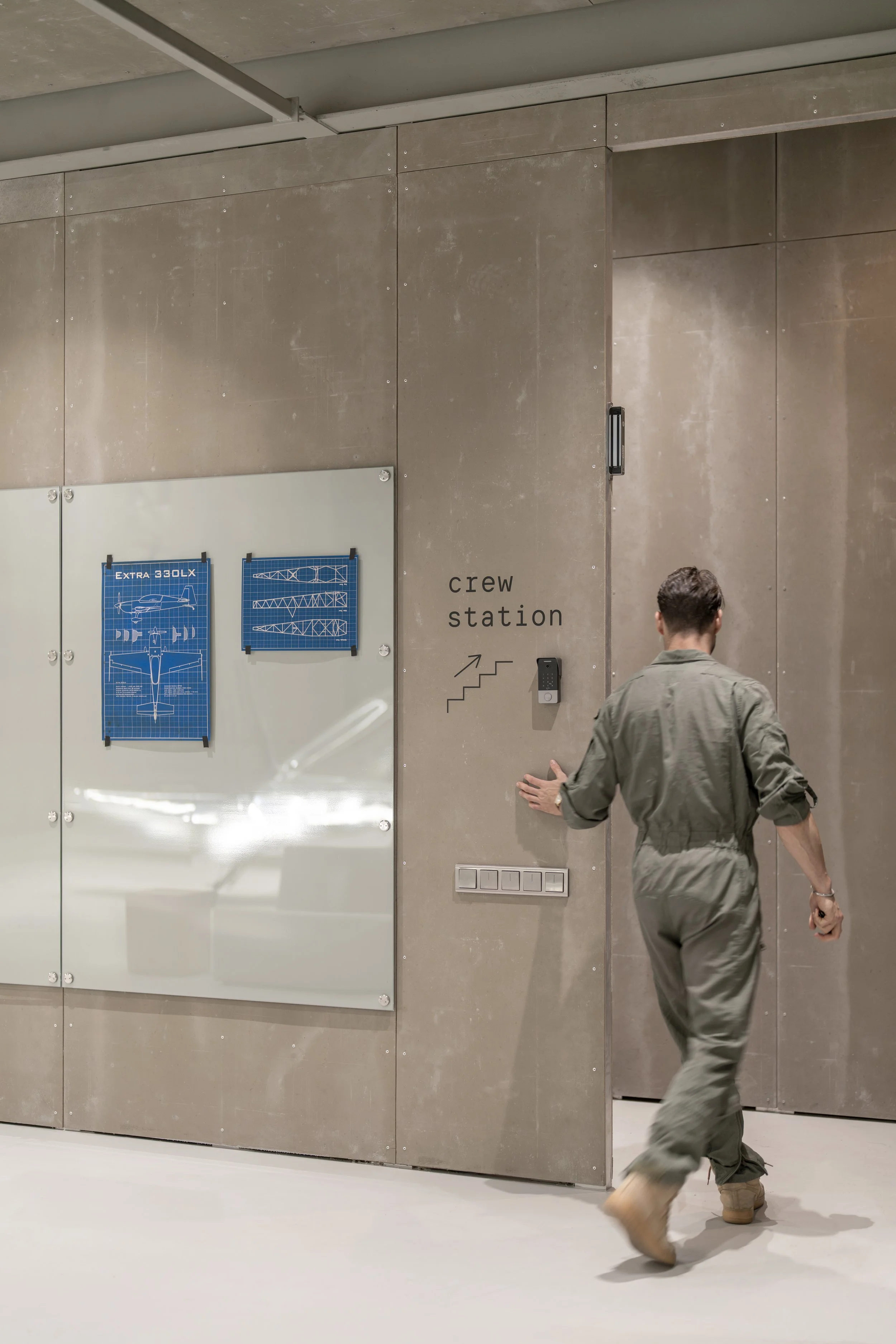

Conditioned by the nuances of the structural framework, segmented board materials were required for the wall finishes. As a result, large-format Cement Bonded Particle Board (CBPB) was selected as a practical solution, offering high durability and allowing for straightforward panel replacement when required.

This particular CBPB texture and colour fully reflect Dan’s vision for the raw materials concept. The panels are deliberately mounted with visible joints derived from aircraft fuselage rivet- fastening techniques, reinforcing the aviation spirit and industrial character.

To ensure cohesive design continuity, the same panels were subsequently used to manufacture doors, worktables, and shelving elements throughout the project, resulting in durable, sustainable material use.

Large-format banners are installed directly into the wall construction via cut-in recesses, following the hangar’s architectural logic. Concealed backlighting is positioned behind each surface, creating a soft, matte illumination. The images communicate aviation culture, the crew’s achievements, aspirations, and discipline while serving as a quiet narrative layer in the project’s industrial integrity.

Lighting is integrated to follow the logic of the hangar’s construction. For general illumination, linear LED lighting is mounted along the steel framing that repeats the structural grid, emphasizing the trusses' rhythm and providing uniform, shadow-controlled light across the main hangar volume.

The Crew Station is located on the second floor and features a single, frameless façade.

This continuous glass surface creates a strong spatial effect—an elevated vantage point from which the entire hangar unfolds in a single gaze. A panoramic sliding central-section window ensures an uninterrupted connection with SPORT aircraft interactions below, amplifying the sense of scale.

Functional observation point suspended above the hangar’s operational core emphasizes clarity and situational awareness—core values of aviation culture.

A shared crew space is organized around a central table for flight task briefings and collective discussions. Adjacent zones are clearly defined yet visually connected, including a leisure area, a compact office, a sleeping space, a changing room with showers, and a kitchen zone.

An on-site–made luminaire, fabricated from aluminum wall-profile offcuts, maintains material continuity while providing focused task lighting and a clear visual anchor for the meeting area.

Seating combines modern ProPro sofas with carefully selected vintage chairs, while red-brown serves as a subtle colour accent within the otherwise monochromatic interior.

Warm wood kitchen cabinets and some furniture elements are partially introduced to balance the raw industrial environment, softening the atmosphere without disrupting the concept logic.

Timur Fatkullin is a dedicated music enthusiast; accordingly, the chosen sound system complements the overall aesthetic.

Wall-mounted glass boards are integrated into the hangar interior to support daily operational workflows, used for aircraft task planning, maintenance scheduling, technical notes, sketching, and crew coordination.

Comfort bulk beds are efficiently arranged, creating an enclosed layout that supports deep rest and proper recharge. Upholstered fabric panels provide acoustic absorption and enhanced sound insulation, minimizing disturbance. Soft, integrated lighting contributes to a subdued atmosphere for mental reset between flights.

The crew changing room is directly connected to the shower area, forming a compact and efficient transition space between preparation and recovery. Benches and rails are executed in durable aluminum wall-profile offcuts, while the shower elements are produced in stainless steel. A bold idea, fully supported by AEROTIM athletes, is to install a transparent glass window connecting the shower area to the main hangar to maintain a direct visual link to the space below.

To define functional zones and soften the industrial character, spot accent lighting is introduced selectively. These fixtures are used to highlight specific areas — such as parked aircraft, stairways, and work or leisure zones at the second-floor Crew Station — creating a more controlled and focused atmosphere where required.

A seamless polymer floor is applied in the main hangar area, while a durable vinyl surface is used on the second level to facilitate easy maintenance. The interior prioritizes clarity, flexibility, and operational efficiency.